Vision inspection systems, length counters and printers for wires, cables & tubes

From our Socials

Machine Learning

Taymer’s vision systems utilize machine learning software to accurately classify various defect types.

This advancement enhances the accuracy of our vision systems, enabling them to differentiate between false and true defects. The software undergoes extensive training to further distinguish and classify defect types such as water spots, pinholes, scratches, and lumps by analyzing a diverse range of classified defect images. After processing sequences of each defect type, the software can perform real-time defect classification during production.

This advanced feature leads to a more precise quality assurance report, empowering your quality control process with enhanced accuracy and reliability in results, ensuring that only genuine defects are flagged for further action.

Vision Systems for All Types of Applications

Taymer’s camera vision systems are used in many plants all over the world. These systems include surface defect inspection, print verification, color verification, dimensional control, as well as product characteristic comparison.

Stemming from the Wire & Cable industry, small defects are detected at very high speeds on continuous products. For the last 25 years, this knowledge has been applied and developed into numerous new applications ranging from catheter inspection to liquid level control, and from offline parts inspection to inline Optical Character Recognition on packages.

Sky is the limit for camera-based applications, be sure to give us a call, book a demo or drop us a line if you would like to discuss how we can support you in your production.

Cable & Wire Length Counter

High accuracy in cable length measurement meters is critical to understanding your costs and ensuring customer satisfaction with your product.

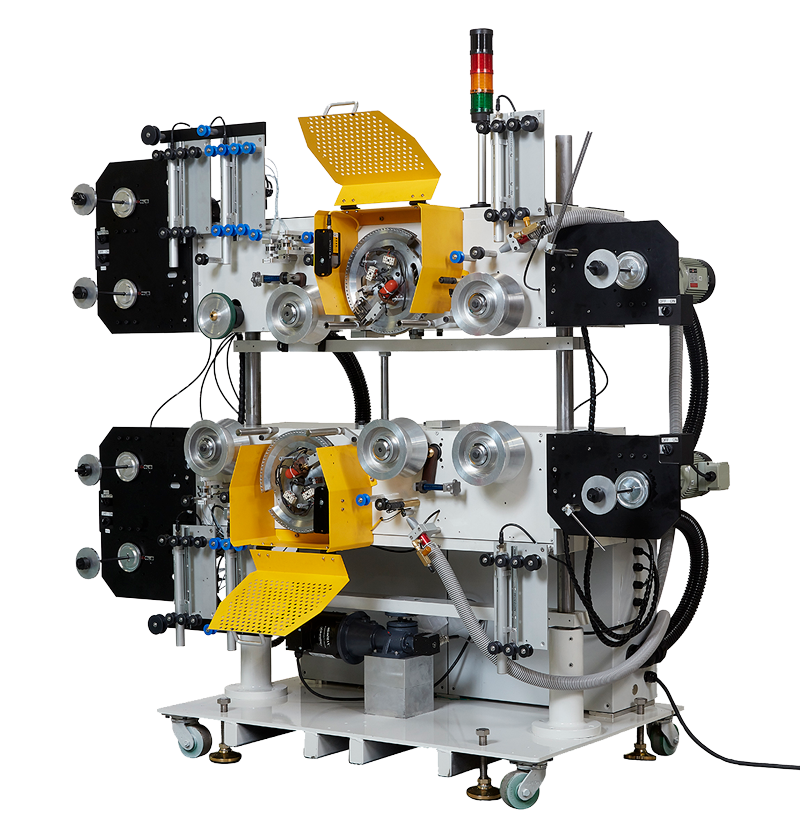

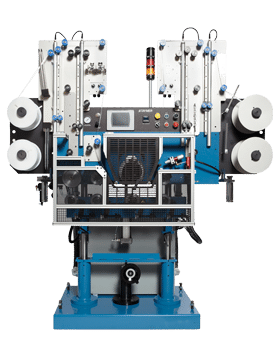

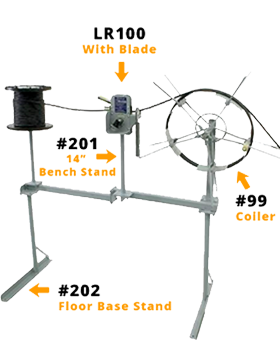

Taymer’s cable length measurement meter solutions include cut to length systems for heavy cable as well as small gauge wire length measurement. Taymer also provides respooling equipment for automated cable length measurement payoff and takeup of cut to length cable measurement.

The Length Rite series are wire and cable length counters that meters accurate length measurement counter results from small diameter wires at low production speeds to large diameter cables at high production speeds. The Length Rite series has been designed for improved wire length measurement accuracy and easy wire length measurement automation.

Reliable and Durable Wire & Cable Marking

For over 40 years, Taymer has been making cable marking machines for wire, cable, pipe and conduit plastic extrusion lines. Through listening to our customers cable marking needs, we have developed innovative cable marking products including Hot Foil, Indent, and Emboss Printers.

Taymer manufactures high and low speed wire printing machines for wire harness fabricators, including continuous hot stamp wire markers and a control jet system for harness fabrication and cable assembly markers, providing printing solutions for the automotive, aerospace and construction industries.