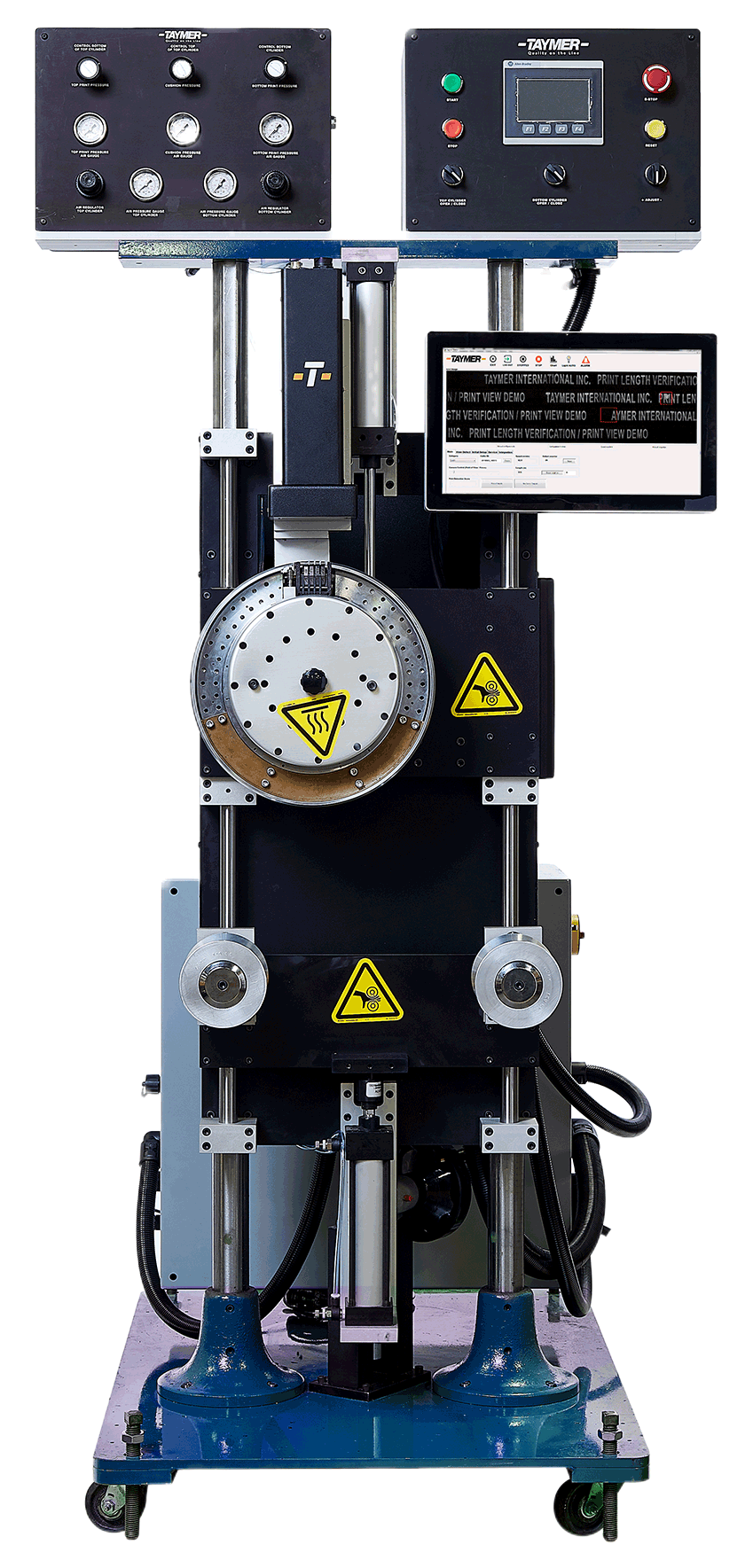

E100

Emboss Printing for Wire and Cable

The Taymer E100 printer is designed for emboss printing on hot product directly after the extruding head and before the water trough in one meter or two foot intervals.

The Taymer 4-digit sequential counter comes standard on the E100 printer. Its industry leading design minimizes maintenance requirements. The E100 is capable of producing clear, durable legends at speeds of up to 1,000 feet or 300 meters per minute.

The ease of operation and setup reduces scrap, production delays and the risk of damage to delicate communication and fiber optic cables. The E100’s robust construction ensures consistent, high quality print even on rigid power cables.

The E100 includes many cost saving features including our unique legend design, precise heat control (optional) and on the fly counter reset.

Features

- Accurate sequential marking in meters or feet

- Cost efficient legend segment mounting system

- Push Button, on the fly counter reset

- PLC control system reduces and simplifies maintenance requirements

- Spring-loaded guide rollers allow trouble free passage of cable bulges

- Casters provide easy movement in and out of the line

- Rugged, heavy duty construction for the production environment

Specifications

- Cable size:

0.2″ to 5″ diameter – 5.0 mm to 125 mm diameter, Larger sizes available on request - Maximum Speed:

up to 1,000 feet per minute or up to 300 meters per minute - Drum Drive:

Direct Friction Drive or optional servo drive - Print Interval Accuracy:

0.9% or optional 0.05% - Type form:

Engraved steel, hardened - Legend Height:

0.0625″ to 0.5000″ – 1.6 mm to 12.0 mm - Print Legend Length:

7 characters per inch – 24 characters per 100mm - Print Temperature:

Closed Loop P.I.D. Controller (optional) - Sequential Marking:

4 digit to 6 digit - Sequential Character Height:

1.6mm to 6mm - Counter Reset:

On the fly, electronic pushbutton

- Machine Layout:

Left to right or right to left - Print Interval:

1 Meter or 2 Feet - Install Location:

Directly after the extruding head, for printing on hot cable - Power Requirements:

208 – 240 VAC 16A, single phase, 50/60 Hz - Compressed Air:

80-100 PSI, dry - Jacket Materials:

Most common jacket materials including: Nylon, Teflon, PVC, HDPE, XLPE - Emergency Stop:

Standard - Machine Weight:

400 lbs. – 180 kg - Machine Dimensions:

- 40″ X 30″ X 60″ (L X W X H)

- 1020mm X 765mm X 1525mm (L X W X H)

- Mounting:

Caster base with leveling screws