We are Taymer.

With more than 60 years of experience producing machines, Taymer International has always been about developing leading-edge equipment including optical quality inspection systems, highly accurate length measurement machines, and various cable printers designed to meet specific needs.

As a world-leading manufacturer of equipment for the wire, cable, pipe, and tube industry, we’ve built an extensive range of solutions designed to provide value and reduce costs to customers on the production line. Having expanded to new industries, Taymer continues growing to meet the increasing demand for highly developed solutions to existing problems in length measurement, in-line quality inspection, and cable printing.

Our Mission

Continuously build, maintain and improve in-line and offline products for manufacturers. Empower our customers with easy-to-use reliable equipment to maximize production and results.

ISO 9001:2015 Certified Quality Management System

At Taymer, we are committed to delivering the highest quality products and services. As part of this commitment, we proudly adhere to the internationally recognized ISO 9001:2015 standard for Quality Management Systems (QMS).

ISO 9001:2015 certification demonstrates our dedication to continuous improvement, operational excellence, and customer satisfaction. This certification means that we have established processes and controls in place to ensure consistent quality in everything we do — from product design and development to delivery and customer support.

By aligning with ISO 9001:2015, we:

- Continuously monitor and improve our processes to meet the evolving needs of our customers.

- Ensure a systematic approach to quality management, reducing risks and enhancing performance.

- Strive for customer satisfaction by focusing on quality, efficiency, and reliability.

Our compliance with ISO 9001:2015 reflects our commitment to quality at every level of our operations. We believe that by maintaining these rigorous standards, we can better serve our clients and strengthen our reputation for excellence.

Taymer leads the field in producing various vision systems to meet the high speed in-line requirements in the production of wire, cable, pipe, tube and similar products. Some of the features that our vision systems can provide are as follows:

- Detect surface defects (Including pinholes, scratches, discolorations)

- Detect diameter defects (Lumps and Neck-downs, incorrect diameter)

- Identify poor print quality and missing print

- Measure print legend interval and re-calibrate the print distance

- Measure wrapping distance, wrapping angle, and other surface features

- Inspect surface color quality

- We often customize our systems to meet specific needs.

Contact us today to see what we can do for you.

Taymer’s wire and cable printer product range covers a wide range of product needs. Taymer printers are robust and we currently have printers that have been running for over 20 years!

Taymer printers include:

These machines are typically installed on extrusion lines or rewind lines running at standard line speeds.

Get in Touch!

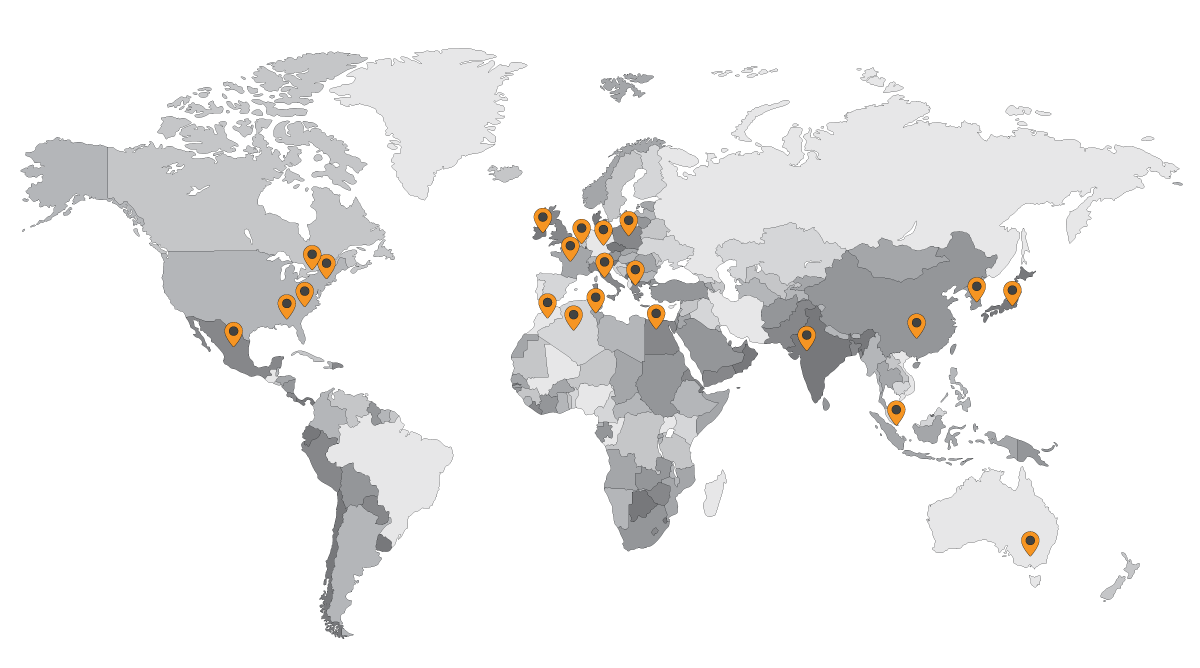

We speak English, Deutsche, Español, Chinese, French, Russian, Turkish, Arabic, Vietnamese, Thai, and Polish. We have offices in 9 different time zones and representatives in another 4. We reply to all questions within 24 hours.

Taymer’s head office and manufacturing facility is located in the Greater Toronto Area in Canada, and we also have offices located in the USA, Germany, Mexico, and China to reach the global market and provide technical support to our customers.