PLV1500

Print Length Verification

Introducing the PLV1500, a precision machine designed to ensure accurate spacing between cable markings. By verifying the exact distance between markings, the PLV1500 helps cable manufacturers save thousands by reducing excess material and delivering precise cable lengths. Perfect for cables, conduits, pipes, and other continuous products, the PLV1500 ensures precise marking accuracy and maximizes production efficiency.

Precise Length Measurement Accuracy

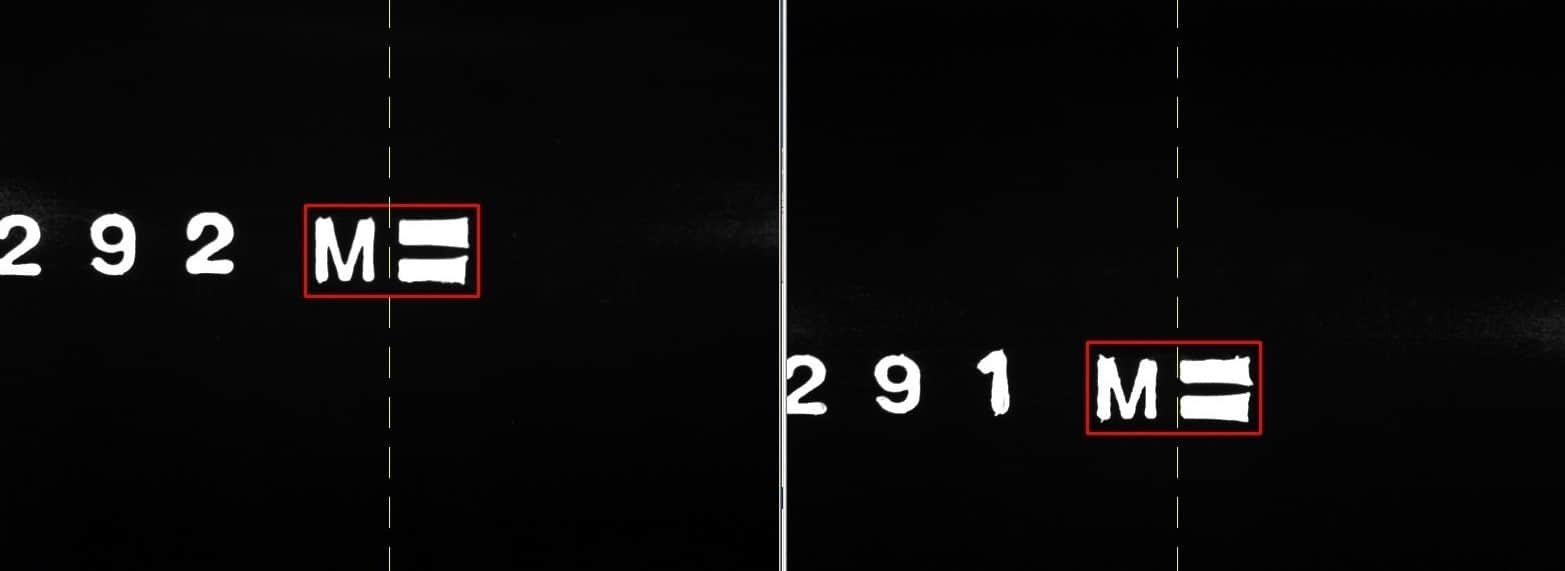

The PLV continuously monitors length marks, ensuring that your cable is marked in precise 1 meter or 2 foot increments. It ensures that your customer gets cable marking that is both accurate and in sync with the rest of your production length measuring equipment.

Continuous On The Fly Recalibration

For Taymer Hot Foil printers, we are pleased to offer a continuous recalibration feedback loop that adjusts length markings according to current actual measurements. The PLV connects directly with the servo drive on your Taymer Hot Foil printer to make adjustments on the fly. Continuous recalibration is also available for ink jet printers at an additional cost to cover integration.

Quality Assurance

Using the Print Length Verification, you can save the length measurement data (Standard Deviation) to disk and print them out to include in your quality reporting both internally and to your customers.

Features

- Allows for automated length verification and automatic recalibration of printed length markings for Taymer HF printers (optionally available for inkjet printers)

- Remote view station allows operators to view current length accuracy statistics from remote locations

- Pulls and displays length data from multiple sources (extruder length Counter, etc.)

- Keeps historical length measurement data

- Each print verified against +/- 0.08 mm per meter certified standard

- Optional Print Verification system

Specifications

- Maximum Line Speed:

450 meters per minute (1500 feet per minute) - Accuracy:

0.08 mm/meter (+/- 0.008%) - Push Buttons:

- Scroll Left/Right

- Freeze Image

- Save Image

- Brightness

- Image Processing:

All images from all cameras are read, enhanced, and analyzed resulting in 100% print legend coverage at maximum line speed - LCD Display:

19″ - Dimensions:

- 30″ x 60″ x 52″ (L x W x H)

- 762mm x 1524mm x 1320mm (L x W x H)

- Custom stands can be built

- Weight:

100 lbs (45 kg)

- Character Size:

- 0.0030″ – 0.500″

- 0.75mm – 12mm

- Camera Configuration:

- 2 cameras: 100% coverage of print legend lengths

- 1 camera: Print verification on the legend (optional)

- Input:

Length measuring encoder - Lighting:

LED - Power:

- 110 V

- 220 V

- Location:

Installed after the printer and water trough