Emboss Cable Printing Machines

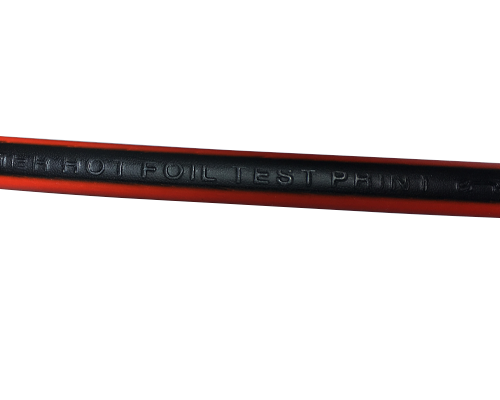

Taymer’s emboss printing technology is ideal for producing raised markings on hot cable jackets. A typical location for these printers is after the extruder. Emboss printing is very similar to indent printing; however, emboss printing creates a print that seems raised from the jacket. This is achieved by ‘indenting’ the jacket around the print and leaving the print untouched. Some models can print on top and bottom of the cable as well as metric and footage.

Taymer’s emboss markers include critical features such as length measurement indicator, on the fly reset push button, and feedback temperature control for print segments.

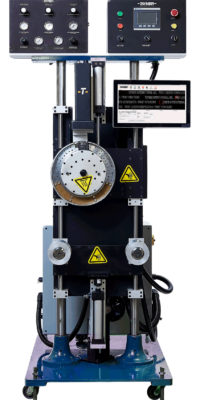

E100

Emboss Marker

The Taymer E100 Printer is designed for emboss printing on hot product directly after the extruding head and before the water trough in one meter or two foot intervals. Optional vision system PV1400 can be coupled with this unit to check the print quality.

E3000

Emboss Marker – Dual Drums

The E3000 printer includes two print drums for emboss printing on top and bottom of cable. Emboss printing is for hot product directly after the extruding head and before the water trough in one meter or two foot intervals. The PV1400 can be coupled with this unit to check the print quality.

Taymer Advantages

On The Fly Reset

An electronic reset is included in the standard Emboss Printer. This unique feature allows the operator to reset the counter with a push of a button on the control panel, on-the-fly, without having to slow down the line.

Numbering Head

A six digit sequential numbering comes standard on the emboss printers. Taymer’s numbering head is easy to maintain and highly reliable: the numbering head can be disassembled, cleaned and reassembled in less than 10 minutes. Numbering heads with up to seven digits or decreasing heads are also available.

Heat Transfer Technology

Unique, mercury contact technology ensures the transfer of power and heat to the print drum is constant at line speeds less than 100 meters per minute. The PID temperature controller will automatically maintain the heat to the drum within 2 degrees C. This ensures a consistent high quality print at all running speeds.

How it works

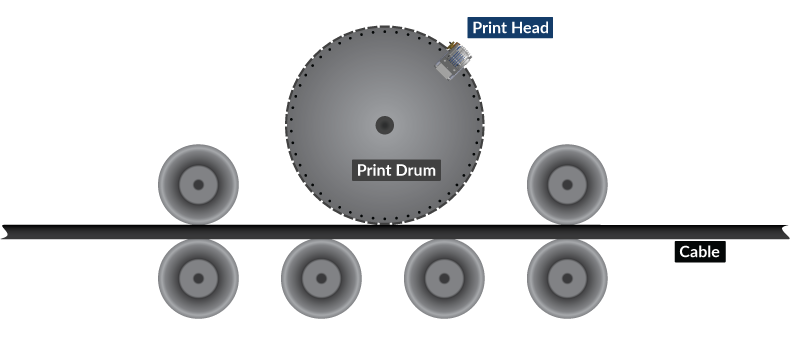

- To print on cables, the operator sets up the print drum with print inserts and a print head.

- The print drum will heat up according to a set temperature.

- As the cable is passing through the printing area, the print drum (with print head and inserts) are rotating at a relative speed.

- At the point of contact between the print drum and the cable, the emboss steel characters presses into the jacket of the cable.

- The heat and pressure exerted on the drum provide a lasting print on the cable.

- The print head will then advance automatically to the next number.