Wire & Cable

For the past 50 years, Taymer has developed multiple applications for the Wire, Cable and Pipe industries ranging from Surface Defect Detection to Print Verification and Cable Marking to Length Measurement. The Taymer technology can be applied inline or offline, on a variety of diameters and line speeds.

Vision & Quality Inspection

Taymer has developed a digital imaging technology that allows operators to monitor print quality of cable marking. Camera inspection of defects reduces printing errors and ensures cable marking equipment is set up properly from the beginning. Surface defects such as lumps, bumps and pin holes can also be detected by surface defect detection equipment.

Taymer’s camera vision systems for inspecting wire, cable, pipe, tube and similar products are used in many plants all over the world. These systems include the Surface Inspection, Print Verification, Band Inspection, Color Verification system and Lump and Neck-Down Inspection systems.

Surface Inspection

The Surface Inspector (SI) is the only camera based inspection system capable of detecting surface defects while displaying and analyzing every square millimeter of your product. The SI series vision systems have been designed to work on a variety of product including: cable jacket, pipe, bar stock or tape. The detectable surface defects include pinholes, bulges, neck downs, surface blemishes, discolorations, tape mis-wrapping, wrinkles, tears and many more.

Print Inspection

Taymer camera inspection print verification is a critical print inspection tool to properly set up your wire marking equipment to free your operators from monitoring print quality. Print inspection and automated verification is critical to ensure your wire marking machines and cable meter marking machines are performing to your customer’s expectations.

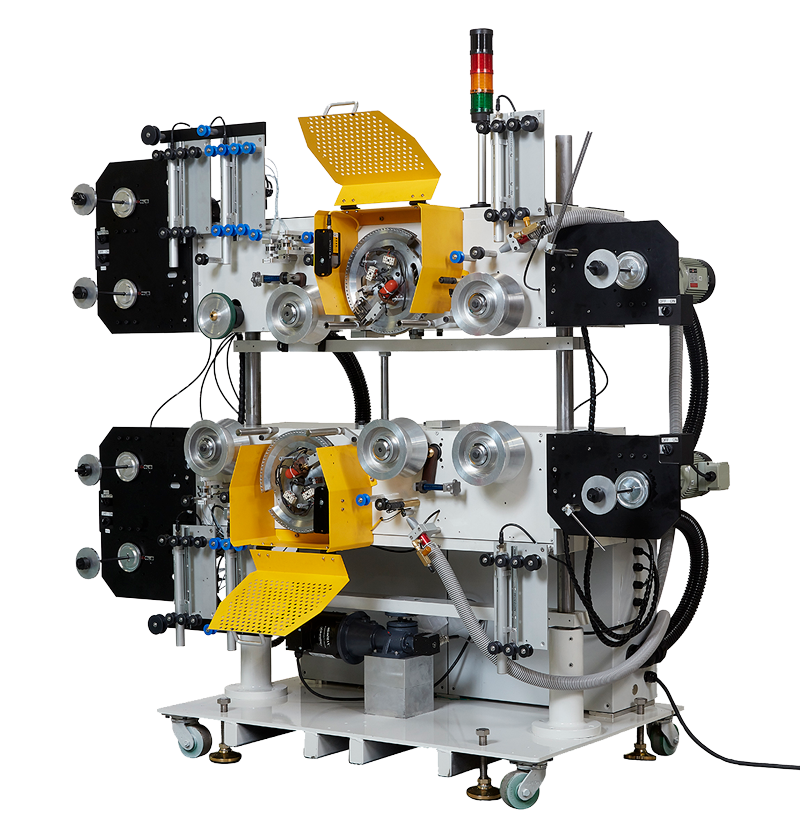

Printing & Marking

For over 40 years, Taymer has been a leading manufacturer of cable marking machines tailored for wire, cable, pipe, and conduit plastic extrusion lines. Through attentive customer feedback, we’ve pioneered innovative cable marking products, including hot foil, indent, and emboss printers. Taymer provides a range of cutting-edge printing technologies to meet diverse cable marking needs.

Our hot foil printing excels in delivering bright, clear, and high-quality markings on challenging surfaces. For raised markings on hot cable jackets, our emboss printing technology, typically positioned after the extruder, creates distinctive raised prints by ‘indenting’ the jacket around the mark while leaving the print untouched. Indent printing technology is designed for permanent markings on cold cable jackets, often placed after the water trough or in a separate rewinding line.

Taymer’s Sinter Printing Technology stands out for producing the most durable colored markings on wire and cable without compromising their electrical or mechanical properties.

Cable Length Measurement & Counters

High accuracy in cable length measurement meters is critical to understanding your costs and ensuring customer satisfaction with your product. Taymer’s cable length measurement meter solutions include cut-to-length systems for heavy cable as well as small gauge wire length measurement.

Taymer also provides respooling equipment for automated cable length measurement payoff and take-up of cut-to-length cable measurement. Our systems include a dedicated velocity indicator and a cable length measurement count indicator.

Length Measurement

Taymer’s highly accurate belt contact cable length measurement devices and meters for wire and cable have many features to enhance productivity and cable length measurement accuracy in your plant. Designed for high speed, continuous process cable length measurement, our device is ideal for the production environment.

Spooling and Coiling

Our wire and cable coiling or reeling machines will speed up your production in your facilities. Whether you are looking for a quick manual cable spooler or a high-speed wire coiling pan device for your Fully Automated Wire Processor, Taymer can provide the solution.