Quality Control & Inspection for Medical Products

Taymer has developed multiple solutions for applications in the medical industry, ranging from surface inspection of single, multi lumens tubes, catheters, and even braided tubing, to pill inspection, counting and color verification. We strive to provide new and innovative ways of ensuring your medical products are flawless and up to industry standards.

We provide inline and offline proven solutions. Please reach out to us via our contact form if you have any questions or would like to discuss your unique application in details.

Medical Tubing Inspection

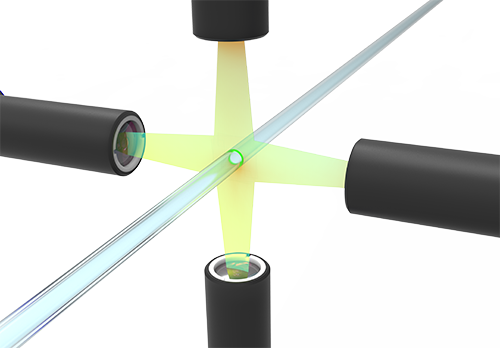

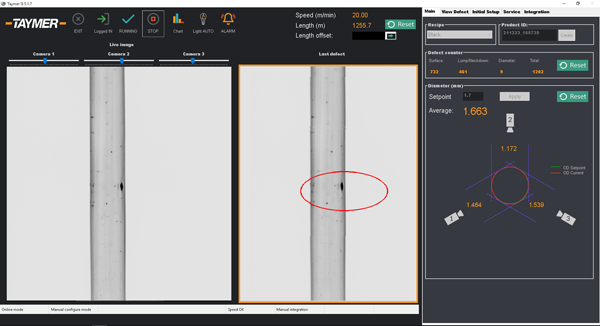

The SI3100-MED is a specially designed version of the SI3100 for the medical tubing industry. This version includes special lighting and programming to detect gels, voids, bubbles, holes, discolorations and other critical defects.

The Surface Inspector for medical tubing (SI3100-MED) is the only tool that can capture, analyze, and judge every square millimeter of your medical tubing product. It is the most thorough method of detecting surface flaws available. With Taymer’s Surface Inspector, you can be sure the product going to your customers meets your high standards and is without surface defects.

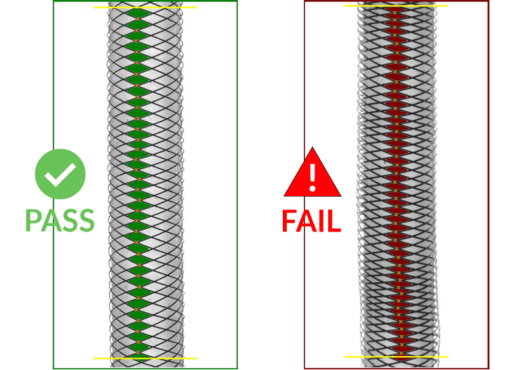

Braid Inspector

Taymer’s braid inspector is a professional measurement of braid density, also known as pick count or picks per inch (PPI) for braided catheters, medical catheters, stents, cables, and other braided products for quality assurance and reliable automated production – Contact us today.

Offline Catheter Inspection

Taymer’s Offline medical product inspection systems leverage the benefits of Taymer’s inspection software over discrete product lengths. The offline Medical Surface Inspection machines can offer complete visual inspection in seconds, and offer total traceability and tracking through customized, secure networks. Taymer has years of experience designing customized product inspection equipment for the medical industry, and our team is well versed in a variety of regulatory requirements – Contact us today.

Pill Counting and Inspection

Taymer’s table-top Pill Counter, PL500, is a camera-based solution for defect verification and unit count. This system can automatically and instantaneously identify and confirm the number of expected pills poured onto the tray.

Our Pill Counter equipment uses a high-speed camera to capture high resolution images in order to distinguish pill shape, size and count. The images are enhanced, magnified and displayed on the console for easy operator verification and interaction. The PL500 will save operators time and prevent possible miscounts.

This application can also be implemented inline.

Custom Applications for Medical Anomalies Detection

Taymer’s SI-MED series is specially designed for the medical tubing industry. These units include modified lighting modules and high speed cameras to detect critical defects and anomalies such as gels, voids, bubbles, holes, and discolorations. Our multi-camera solutions are currently used on production lines extruding with Silicone, PE, PEEK, PTFE, TPE and more.

Taymer’s vast experience with designing and implementing custom solutions give our systems the high-level performance needed, all while maintaining industry standards and regulations.