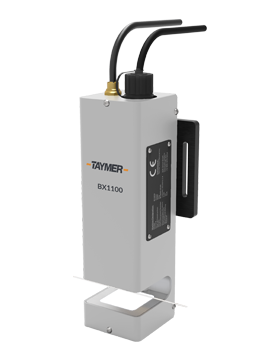

BX1100

Braid Inspector and Pick Counter

The BX1100 is a braid inspector and pic counter that you can rely on for dependable quality control. This advanced tool specializes in measuring the braid density and picks per inch (PPI) for braided catheters, stents, cables, and other products. The system is equipped with custom lighting and digital imaging to provide you with real-time inspection capabilities. The results are displayed on a monitor in enhanced and magnified images allowing you to confirm the integrity of braids and swiftly detect any errors.

The BX1100 can be integrated inline with horizontal or vertical braiders, automating the inspection process. It can also be utilized offline as a tabletop unit where operators can conduct fast and effortless inspections.

Contact us today for more information

Features

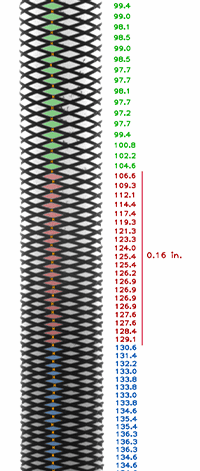

- The braid Inspector is designed to measure braid density and count picks within a desired length

- The high resolution cameras and custom-designed lighting system increases the accuracy of the braid inspection

- Digital images are captured and analyzed automatically by the software to give you results in real time

- This system can be used in a continuous inline or offline configuration

- This system can be mounted inside a horizontal or vertical braider enclosure

- It can be integrated with the braider to control production and improve your process

- The BX1100 has a small footprint, simple set-up and is easy to handle by operators

Reduced Surface Defects

With the BX1100, operators can see current surface images and the latest defect dimensions easily.

The real-time information flow, especially failure data, helps operators pinpoint braided imperfection causes quickly.

Identifying when and how a defect happens allows your technical staff to reduce the occurrence of surface defects and prevent customer complaints and rejects.

Quality Assurance

The braid inspector and pick counter will capture images of your products, save the images for you to include in your quality reports.

The user interface also makes it easy for engineering and production supervisors to examine the defect without having to see the defect itself. Defect locations are recorded together with the image of the defect allowing your operators to find and eliminate defects before they reach your customers or fail in the field.

Specifications

- Maximum Speed:

328 feet per minute | 100 meters per minute - Maximum PPI:

Up to 300 PPI | May vary based on application - Minimum Product Diameter:

0.004” or 0.1 mm - Minimum Braid Size:

0.0004” or 0.01mm - PLC Integration:

Integrates with most models of PLC including Siemens and Allen Bradley - Shaft Types:

- Transparent/multi-lumen/opaque tubes

- Polymers

- Rigid metal mandrel

- Braid Types:

- Metal/polymer/fiber single wire

- Multi-wire bands

- Flat/ribbon-style wires

- Various braid patterns

- Mount:

- In horizontal braider

- In vertical braider

- In reel-to-reel system

- offline tabletop

- Lighting:

LED - LCD Display:

22″ - Power:

- 110 VAC 50/60 Hz

- 220 VAC 50/60 Hz

- Capture system dimensions:

- (4” x 4” x12”) to (6” x 6” x 15”)

- (102 mm x 102mm x 205mm) to (153mm x 153mm x 381mm)

- Dimensions will vary depending on application requirements