SI3100-MEDX

Offline Catheter Surface Defect Inspector

The Offline Surface Inspector for catheters (SI3100-MEDX) scans and records your catheter product in order to locate holes, lumps, neckdowns, scratches, and other critical surface defects. With Taymer’s Surface Inspector, you can be sure the product going to your customers meets your high standards and is without flaws.

Looking for other medical solutions? Click here

Reduced Surface Defects

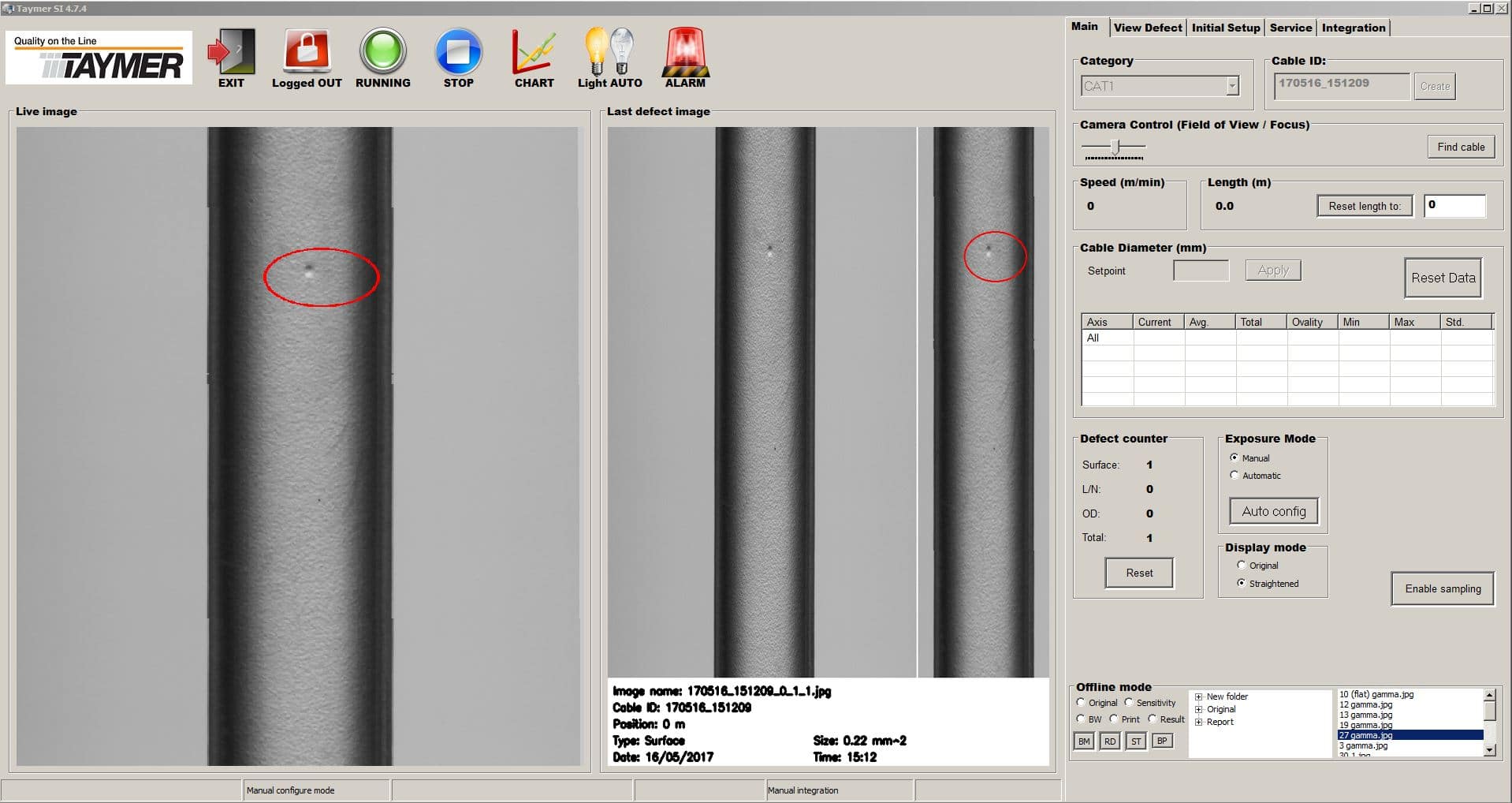

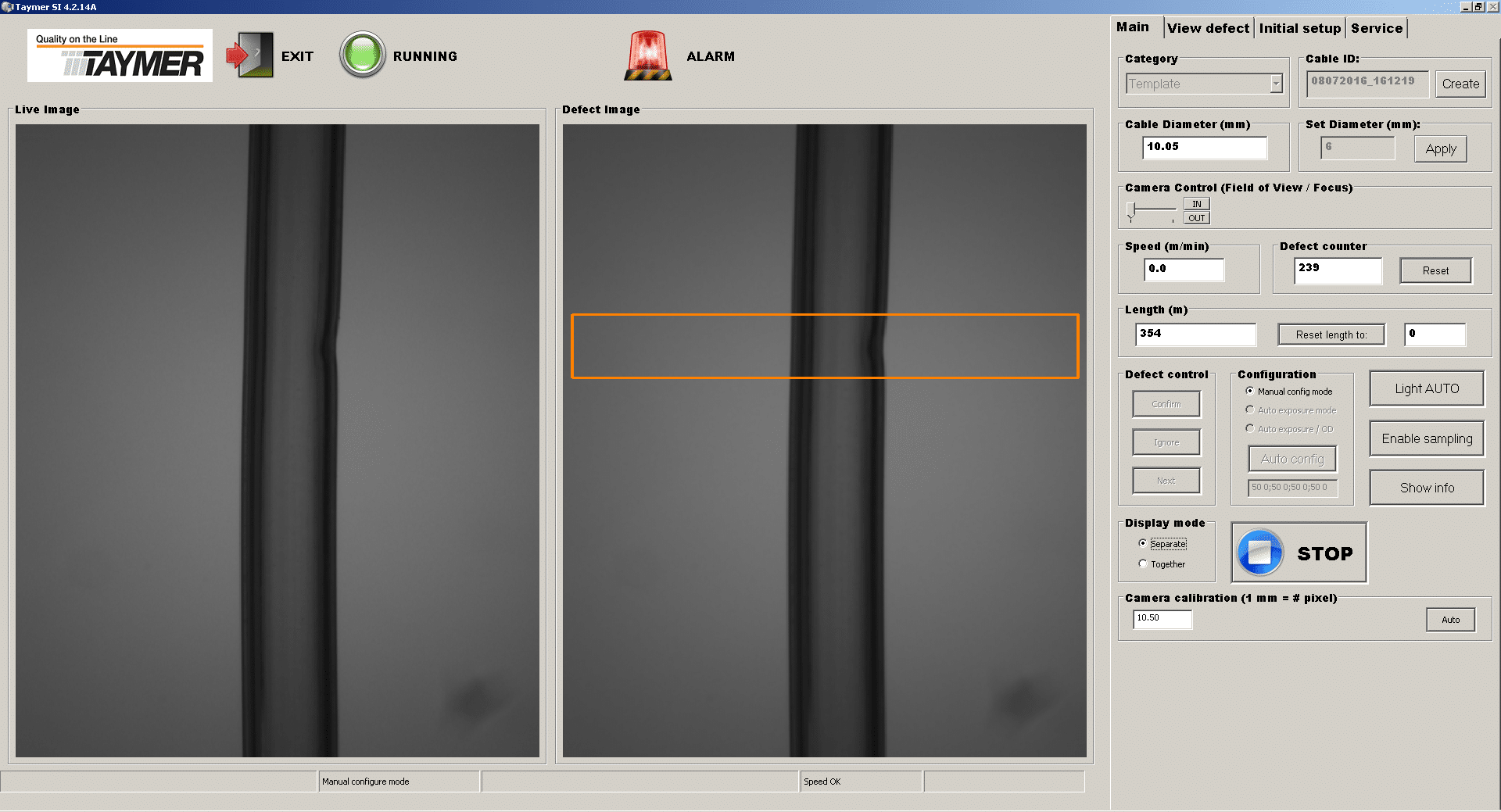

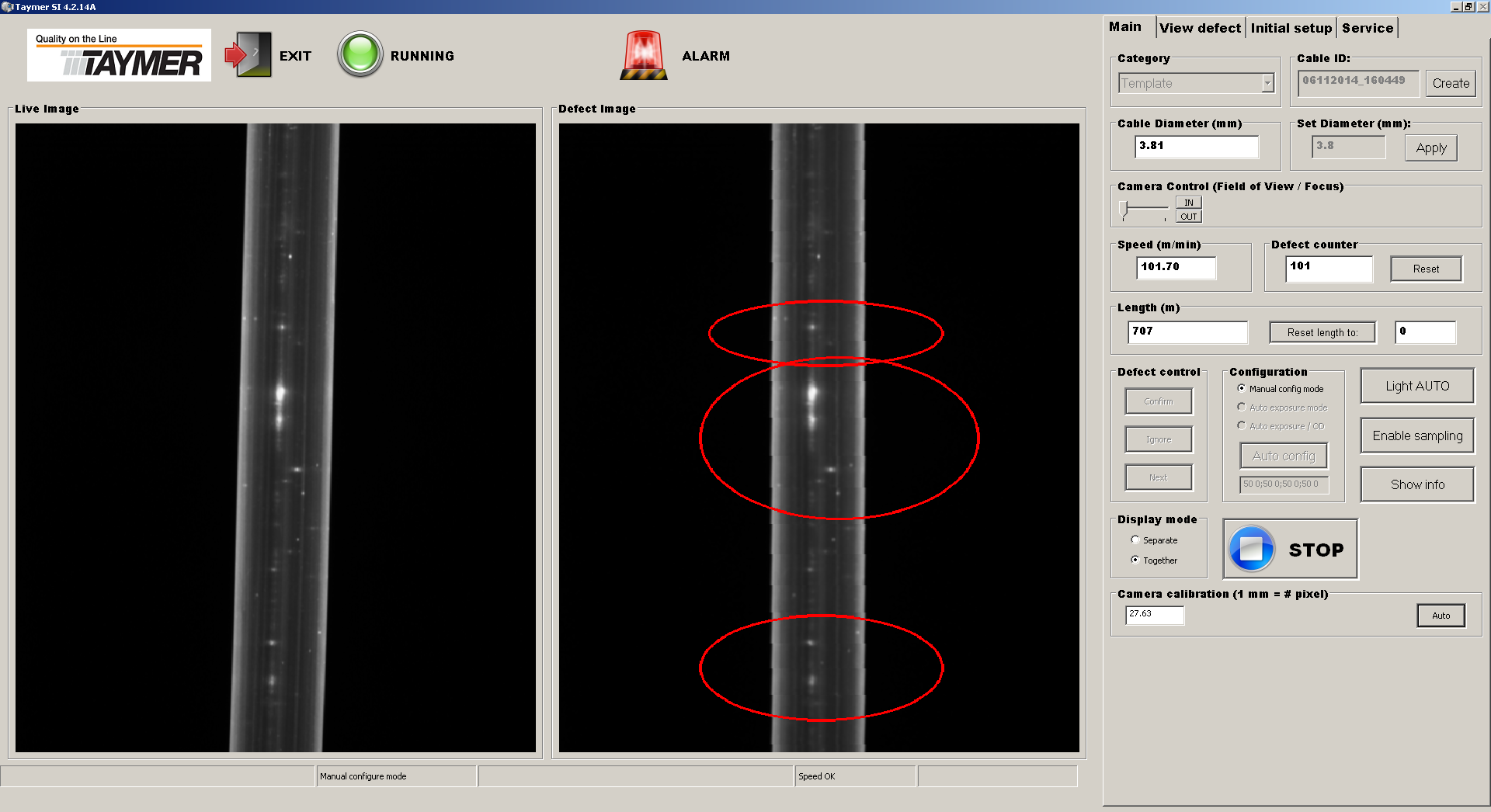

Our offline surface defect inspector for catheters empowers operators with real-time information, offering a comprehensive view of current surface images and the latest surface defects, along with their corresponding dimensions. This stream of data enables operators to effectively isolate the causes of surface imperfections, allowing your technical staff to prevent customer complaints and rejects.

By precisely identifying how defects occur, your team can implement targeted improvements, minimizing the likelihood of future defects and enhancing overall product quality. With up-to-date surface images and detailed defect dimensions at their fingertips, operators can closely monitor catheter quality during manufacturing, taking immediate action to address any issues detected.

By proactively addressing the root causes of surface defects, your organization can deliver catheters of the highest quality, meeting the stringent standards of the medical industry and mitigating the risk of customer dissatisfaction and financial losses. Our dedicated focus on providing advanced inspection solutions ensures that with our offline surface defect inspector, you can enhance your manufacturing process, improve product reliability, and strengthen customer satisfaction.

Quality Assurance

The SI3100-MEDX offers comprehensive functionality to capture high-quality images of your catheters. It enables you to conveniently save these images to disk and print them out, facilitating effective quality reporting both internally and to your customers.

Additionally, the system records defect locations along with corresponding images, empowering your operators to swiftly identify and eliminate defects before they impact your customers or result in field failures. With this powerful tool at your disposal, you can ensure that only flawless catheters reach your customers, enhancing overall product quality and customer satisfaction.

Features

- Detects gels, voids, pinholes, bulges, neckdowns, contaminants, blemishes, and scratches on catheters

- 3 camera configuration to provide 360° coverage of product surface and 100% of product length

- Includes customizable stainless steel enclosure and industrial stand

- Alerts operator and production machinery if any defects are found

- Records any defects for QA records and operator verification

- Accurately measures and records catheter diameter along 1 or 3 axes

- Saves location information for each defect to allow operators to easily find the defects after detection

- Generates reports containing relevant product diameter, defect, and measurement information

Specifications

- Minimum detectable defect size:

0.025 mm and up | 0.001″ and up - Outer Diameter Range:

0.01 mm – 30 mm | 0.0004” – 1.18”

Other diameters available upon requests - Camera Configuration

3 camera – 100% coverage of tube circumference

Custom configuration available on request - Pixels per square mm

~1,500 for small diameter catheter - Percent overlap between images:

5% - Image processing:

All images from all cameras are read, enhanced and analyzed, resulting in 100% product coverage - Lighting:

LED

- Type of defects detected

- Gels

- Voids

- Pin Holes

- Neck downs

- Bulges

- Scratches

- Contaminants

- Discolorations or other imperfections

- Power Supply:

110V or 220V, 50/60 Hz