3D Printer Filament Inspection

3D Printing has revolutionized the manufacturing process, being used in industries that range from casual prototyping to aerospace component manufacturing. For 3D printer filament manufacturers looking to supply only the highest quality filament to their buyers, Taymer provides an innovative filament solution that will give your facility the confidence and capability you need to deliver exceptional 3D printer filament. Eliminate waste, facilitate production, and enhance customer satisfaction by purchasing our 3D Printer Filament Inspection equipment for your manufacturing facility.

Identify Defective Filament with our Surface Inspection (SI) series

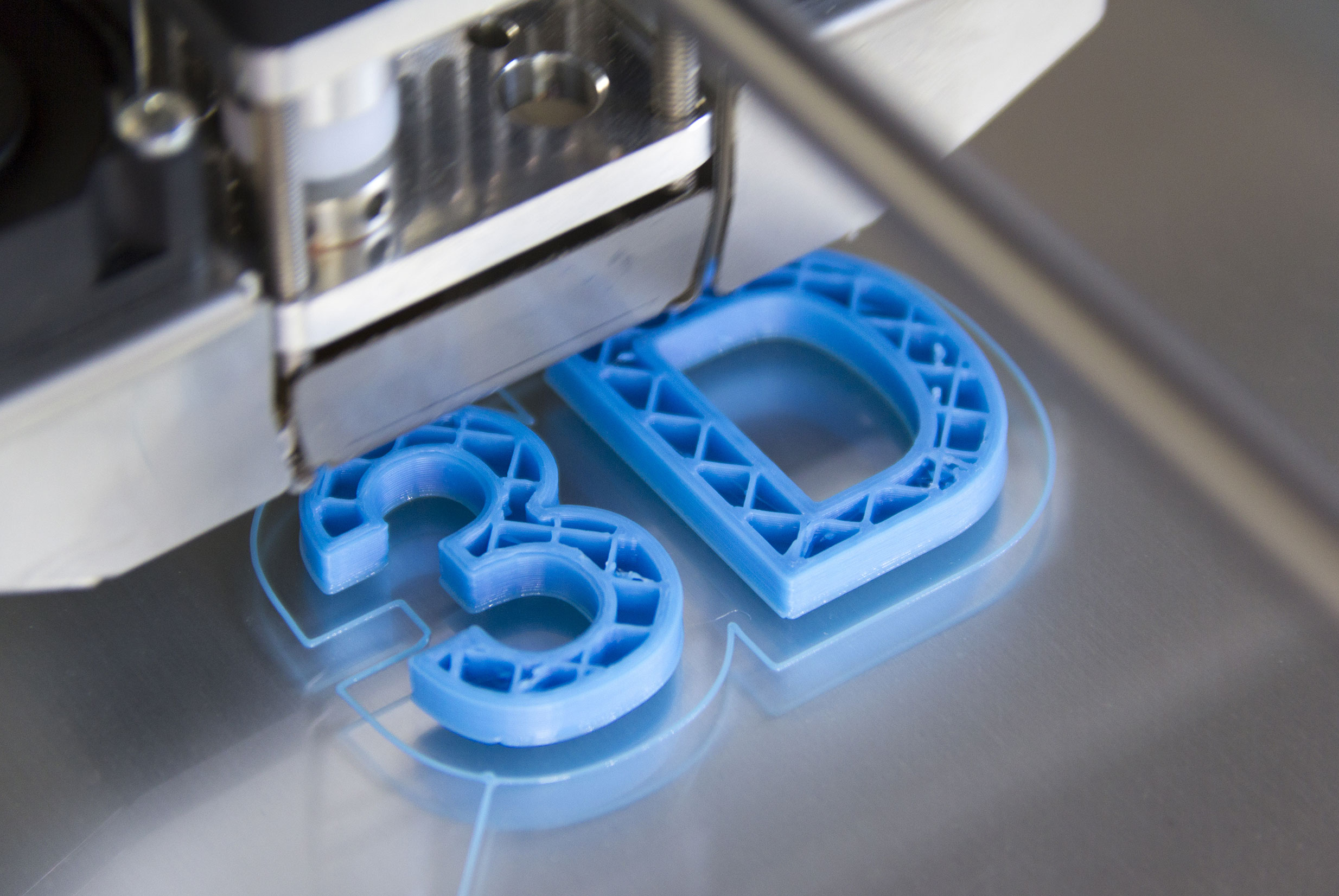

Despite being a highly advanced piece of technology, the integrity and appearance of 3D printwork can be easily compromised by poor quality or defective filament.

If left unchecked, defective filament can result in a poor-quality print job that will consequently cause unwanted costs and delays to both your buyer and their own customers.

Defective filament can also lead to nozzle damage to the 3D printer itself, an incident no filament manufacturer wants their buyer to experience. A damaged 3D printer will incur heavy servicing and cleaning expenses that can easily cause a financial burden for your buyer and negatively affect the reputation of your filament company as a result.

Our 3D Printer Filament Inspection solution eliminates the risk of defective filament and gives your buyers greater confidence in your company as their preferred supplier with spot-free filament. Just like our wire inspection technology, our filament inspection technology judges filament to ensure a perfectly round profile with no variation on both its diameter or surface appearance.

Surface & Dimensional Inspection

Our SI3100 Surface Defect Detector provides a complete inspection that locates and judges any defects to the precision of a single square millimeter. Recommended for inspecting the full circumference of your 3D printer filament, this detector captures images that can be easily digitally shared or printed for further review by technicians.

Dimensional Inspection

Specifically designed for detecting lumps or neckdowns that are not visible on the surface, Taymer’s Lump and Neckdown Detector is able to capture images that identify any variation within the diameter of your 3D printer filament. We also provide software that will assist technicians in inspecting any lumps or neckdowns, as well as assessing whether action is required. Learn more about this unique tool by contacting our sales team today.

Supported 3D Printer Filament Materials

Our machines are well-suited for inspecting a wide variety of different 3D Printer filaments, including popular materials such as:

- ABS (Acrylonitrile Butadiene Styrene)

- ASA (Acrylonitrile styrene acrylate)

- CF Nylon

- HIPS (High Impact Polystyrene)

- Nylon

- PC (Polycarbonate)

- PEEK (Polyether Ether Ketone)

- PETG (Glycol-modified Polyethylene Terephthalate)

- PLA (Polylactic acid)

- TPU (Thermoplastic polyurethane)

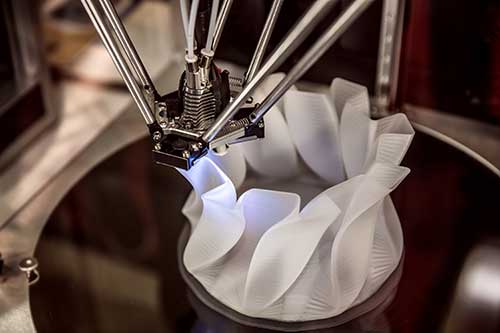

Obtain Flawless 3D Printwork Every Time

Give your consumers the consistency and quality they deserve, purchase our 3D printer filament inspection machine by contacting Taymer. We specialize in providing impeccable quality control solutions, including for those in the 3D printing industry. With both our 60 years of experience and our forward-thinking initiative, we pride ourselves on supplying our clients with robust inspection solutions that will provide manufacturers and their consumers with the peace of mind they deserve for exceptional products. If you have any questions regarding 3D print filament, please do not hesitate to contact our team for more information.