Cable and Wire Printing and Marking

Cable Marking

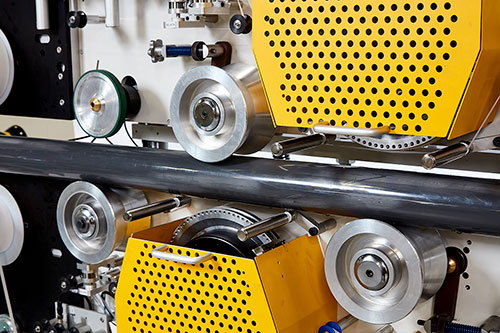

For over 40 years, Taymer has been making cable and wire printing machines for wire, cable, pipe and conduit plastic extrusion lines. Through listening to our customers cable marking needs, we have developed innovative cable marking products including Hot Foil Printers, Indent Printers, Contact Ink Printers and Inkjet Solutions.

Wire Markers

Taymer manufactures high and low speed wire printing machines for wire harness fabricators, including continuous hot stamp wire markers and a control jet system for harness fabrication and cable assembly markers, providing printing solutions for the automotive, aerospace and construction industries.

Taymer’s Printer Benefits

Our Hot Foil Printers and Wire Hot Stamping Machines are economical to purchase and operate. All wire and cable marking machinery is manufactured in North America from locally available off-the-shelf components. Manufacturing is handled entirely by Taymer to ensure adherence to the standards and tolerances that have made the wire harness hot stamping machine the most reliable and rugged on the market. Our approach to hot foil printing for cable allows us to set new standards in print quality, accurate length measurement, reliability and ease of operation.

And now we have extended our product range to include wire and cable length measurement equipment as well as camera inspection systems for print verification and much more. For optimal quality and productivity, you can combine a Taymer printer with cable length measurement equipment or camera inspection print verification. Taymer’s cable hot foil printers can also be factory outfitted with the camera inspection system for print verification.

Cable and Wire Printing Quality

Our Unique Print Head provides dependable long term operation

Each wheel is hardened, ground and polished through our custom process to prevent sticking and pre-advancing. Its recessed design reduces friction and ensures accurate advancing.

The advance latch housing is fabricated from a steel alloy to ensure no distortion of shape under load. Our “positive lock” feature prevents the print wheels from jumping ahead more than one increment per revolution.

The rest of the machine is just as robust. We have refurbished heads over 20 years old where many of the original components such as shafts, wheels and cams were reusable.

Our superior print quality is the result of several factors:

- Drum temperature control improves print quality with constant and accurate temperature

- Print inserts are engraved to strict tolerances and character size can be specifically tailored to customer requirements

- A PLC adjusts and synchronizes the drum and cable speed for superior quality and length measurement accuracy

- Our Cable and Wire Printing Machine design maximizes the amount of pigment applied to the cable to ensure crisp, bright print.

- The design of the guiding system and print drum ensures the print is clear and complete even if the cable is changing shape or rotating

- Our Unique Print Head provides dependable long term operation

Accuracy & Cost Effectiveness

Our thirty five years of experience has resulted in a printer which adjusts the speed of the drum every 2 milliseconds. You are able to adjust the length numbering in increments of +/-.001 to ensure that excess cable is not produced.

In addition, tape is advanced only when printing so that there is no wasted tape for areas of the cable without a legend. Our equipment can also be interfaced to a laser-measuring unit if desired.

Reliability

We are the designers, builders and maintainers of all our equipment . Our equipment is tested extensively before shipment to confirm everything is working to specification.

When service is required, we offer a complete inventory of parts and accessories and are available for support and advise through a toll-free support number.

Ease of Use

Our customers find that they can disassemble, clean and reassemble the Taymer print head in less time than it takes to just disassemble the print heads they used previously. The machine is less complicated and easy to maintain, the result of an overall better design. Other key features include:

- Ability to print in both feet and meters – a switch over can be accomplished in minutes or on the HF 4000, immediately

- Dual Tape spools and accumulators allowing continuous operation and eliminating tape splicing

- One the fly, manual or automatic reset of the sequential printing head without loss of measurement

Support

Taymer understands the wire and cable marking industry and the maintenance and production challenges you face on a day-to-day basis. The quality of our hot foil printing and hot stamping machines allows us to stand behind them with confidence.

The simplicity of our hot stamping machines make installation very quick and painless allowing you to focus on fulfilling your customer orders. Our robustly designed hot foil printers will withstand the rigors of the production environment, giving you many tens of years of continuous service.

If you should happen to have a problem with your hot stamping machine, hot foil printer, camera inspection system, give us a call on our toll free number and let us deal promptly with any issue that may arise. Let us take the hassle out of the wire and cable marking process.