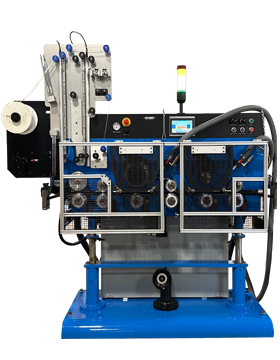

HF4000

Double Drum Hot Foil Printer

The Taymer HF4000 Hot Foil Printer is designed for printing without any interruption in production. While one job is running, the alternate print drum can be set up for the next job. A flick of the switch transfers the printing from the one print drum to the next. Footage only, metric only and footage and metric models are available.

A built in microprocessor controls all aspects of the marking process and adjusts the machine to suit the changing conditions and speeds of the production line. Clear durable legends are produced at speeds up to 450 ft/min (150m/min).

The ease of operation and setup reduces scrap, production delays and the risk of damage to delicate communication and fibre optic cables. A dual tape spool and tape accumulator system eliminates print interruptions.

These standard features and more make the Taymer HF4000 a new generation in wire and cable printing.

Features

- High accuracy sequential marking in meters or feet

- Reset to zero on the fly

- Length adjustments in increments of ± .001

- Dual tape spools and accumulators eliminate tape splicing

- Microcomputer controlled adjustments reduce the need for operator intervention

- Adjustable guide rollers prevent damage to cables

- Casters for easy movement in and out of the line

- Rugged, heavy duty construction for the production environment

- Optional automatic tape spool changer to avoid down time

Specifications

- Cable Size:

0.2″ to 5″ dia. (5.0 mm to 127 mm) - Maximum speed:

- up to 600 ft/min. (footage mode)

- up to 200 m/min. (metric mode)

- Drum Drive:

Micro controlled brushless servo - Print Interval Accuracy:

1 : 1,000 - Correction Adjust Increments:

1 part in 1,000 ± - Type Form:

Engraved steel, hardened - Character Height:

1/16″ to 5/16″ (1.6 mm to 8.0 mm) - Print Legend Length:

240 characters metric or 120 characters footage at 7 characters per inch - Print Colours:

White, black, yellow (others on request) - Spool Length:

- 3/8″ x 42,000 feet

- 1/4″ x 72,000 feet

- 10 mm x 12,805 m

- 6 mm x 21,951 m

- Spool Capacity:

2 - Print Temperature

Micro controlled (P.I.D.) - Sequential Marking:

6 digit

- On The Fly Reset:

Yes - Machine Layout:

Left to Right or Right to Left - Print Interval:

Metric or Footage - Power Requirements:

280-240 V, 16A, single phase, 50/60 Hz - Compressed Air:

100 psi @ 5 to 10 CFM, dry - Jacket Materials:

Nylon, PVC, Med & HDPE, various cross-linked and semi-conductive materials - Spent Tape Takeup:

Vacuum - Fault & Warning Signals:

8 digit status display and warning light - Stopped Line Response:

Automatic lift carriage drop - Emergency Stop:

Standard - Machine Weight:

545 kg (1,200 lbs.) - Mounting:

Caster base with levelling screws